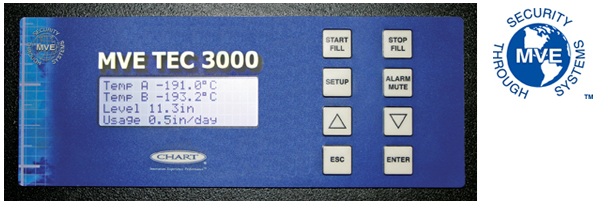

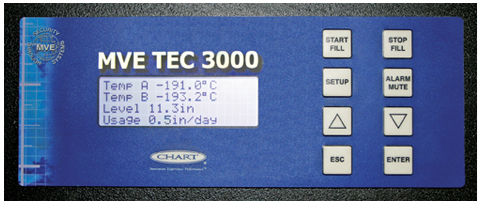

The TEC 3000 employs a variety of advanced features that enable the controller to monitor and control the environment inside a freezer with a high level of precision.

Liquid Nitrogen Level Measurement

The TEC 3000 uses a differential pressure system to determine the LN2 level to an accuracy of ± 0.5 in. (15 mm) and a resolution of 0.1 in. (5.0 mm). Unlike alternative level sensing systems, differential pressure allows the exact level to be measured and displayed. Using the simple single point calibration in a range of 3.0 in. to 48.0 in. (75 mm to 1220 mm), the patented, self-maintaining, closed-loop system displays in inches, millimeters, or a percentage full.

Automatic Liquid Nitrogen Level Control

The fully automated LN2 level control system is based on user-defined parameters that can be electronically adjusted over the entire level range. The parameters include Low Level Alarm, Low Level Fill Point, High Level Fill Point and High Level Alarm. The redundant Dual Solenoid Valves for overfill protection run on 24 VDC, 1.0 amp (max).

Liquid Usage

This exclusive feature provides an estimation of liquid usage to track LN2 consumption and can provide an early failure warning to allow sufficient time to implement corrective action and save irreplacable samples.

User-Defined Alarms

A total of 17 audio/visual alarms are used to alert the user to any potential or developing problems. The alarms include: High Temperatures, Low Temperatures, High Level, Low Level, Liquid Usage, Maximum Fill Time, Gas Bypass, Temperature Calibrations, Low Battery, Power Failure, Lid Open and Communication Loss.

Remote Alarm Monitoring

The TEC 3000 Alarm monitoring includes a Global Remote Alarm Relay, as well as four discrete contacts for

High Level, Low Level, Temp A High and Low Battery.

Temperature Measurement

Two independent temperature measurement channels are employed to accurately measure the temperature across the entire storage space. The two platinum RTD sensors have an accuracy of ± 1.0°C and a resolution of 0.1°C. The temperature can be displayed in °C, °F or K. The single or two point calibration also has altitude compensation for the highest accuracy.

Hot Gas Bypass

This unique feature is able to vent warm nitrogen gas from the supply line before initiating a fill. This prevents warm gas from entering the freezer space, which helps maintain a stable temperature gradient and increases the efficiency by reducing excess LN2 evaporation.

Event Log / Data Storage

The TEC 3000 is able to store vital, unalterable, time-stamped data in nonvolatile memory. This is a great tool for assessing freezer performance and troubleshooting any problems. The memory can store 30,000 events, an estimated 10 years of storage capacity. The data includes time-stamped temperatures, LN2 level, liquid usage, and any alarms or events.

Password Security

The multilevel security system comprised of up to ten user-specific programmable passwords and four security levels can be customized to grant or restrict personnel access to certain menus and settings.

Communication Capabilities

Two independent ports can be used to communicate with other TEC 3000 controllers, a remote PC, serial printer, or other RS-485 networks and devices. Options include

ASCII, MODBUS, Printer and One Fill All Fill (OFAF).