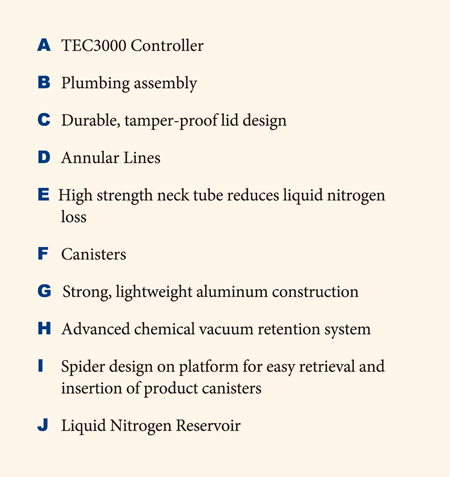

The MVE CryoSystem 6000 Full Auto combines the compact efficiency of aluminum dewars with the monitoring and auto fill features of the TEC 3000 control system. The differential pressure-based level control allows this unit to easily be used for liquid or vapor storage with a -190°C top box temperature. The TEC3000 continually monitors and records temperature and LN2 levels, auto filling when needed, and providing audio/visual alarms with remote connectivity when necessary. The enhanced safety factor of not having to manually fill this unit also helps maintain a consistent temperature profile for vapor storage.

The CryoSystem 6000 Full Auto provides the convenience and security of high capacity stainless steel freezers for your average sized sample collection at a fraction of the price.

- ●Fully automatic LN2 level control and temperature monitoring

- ●Can be used for liquid or vapor storage

- ●Tracks and displays LN2 consumption

- ●17 user-defined audio / visual alarms including High Temperature, Low Level, Liquid Usage, Fill Timeout, and more

- ●Remote monitoring and communication capabilities

- ●Electronically stores up to 10 years of unalterable, time-stamped data events for traceability and troubleshooting

- ●Transportable in emergencies or in the event of natural disasters

| CryoSystem 6000 Full Auto | ||||

| Maximum Storage Capacity | ||||

|---|---|---|---|---|

| Number of Canisters | 6 | |||

| Number of 1.2 & 2.0 ml vials 100/box | 6000 | |||

| Number of 1.2 & 2.0ml via 25/box | - | |||

| Boxes per Rack | 10 | |||

| Performance | ||||

| LN2 Capacity L | 175 | |||

| Static Evaporation Rate L/day | 4.0 | |||

| Unit Dimensions | ||||

| Neck Opening in.(mm) | 8.5(216) | |||

| Overall Height in.(mm) | 37.9(963) | |||

| Outer Diameter in.(mm) | 26.5(673) | |||

| Weight Empty lb.(kg) | 156(70.7) | |||

| Weight Full lb.(kg) | 478(216.8) | |||

* Static evaporation rate and static holding time are nominal. Actual rate and holding time will be affected by the nature of container use, atmospheric conditions, and manufacturing tolerances.

** Normal Working Duration is an arbitrary reference, to estimate container performance under normal operating conditions. Actual working time may vary due to current atmospheric conditions, container history, manufacturing tolerances and any individual patterns of use.